Best Acceptable Quality Limit Inspection in China

Wandering around for Acceptable Quality Limit inspection experts?

Leeline SOURCING is a TOP-NOTCH sourcing company. We put every type of SOLUTION ahead. All our SUPPLIERS meet the client’s specifications. It turns out to be the BEST CHOICE for you.

Grow your BUSINESS with our FLAWLESS services.

5,000+

Completed Projects

4,000+

Happy Clients

135

Countries Represented

100+

Professional Staffs

Our services

Get an AQL Quality Check With Leeline Sourcing

In DUPRO inspection, LEELINE sourcing dedicates an EXPERT inspector. Our inspector checks AQL values. Establish the PERFECT criterion. And JUDGE your SUPPLIER to be compatible with different AQL levels.

Product Functionality

Is your PRODUCT working fine? If there are any defects, we SORT out in product inspections. The Supplier has to QUALIFY for standard product FUNCTIONING. You get PERFECTLY working items as per your NEEDS.

Get HIGH STANDARDS of INVENTORY with ACCEPTANCE criteria.

Product Performance

We run the PRODUCT through our INSPECTION. It FINDS out a CRUCIAL performance of the PRODUCT. Whether product PERFORMANCE is up to mark or not. You get ONLY HIGH-PERFORMANCE products with NO DEFECTS.

Get the BEST inventory with our INFLUENCE.

Product Durability

Long-standing products are our GUARANTEE. Our AGENT checks the PRODUCT’s durability. In-depth INSPECTION highlights the MATERIAL quality of the PRODUCT. WithHIGH-QUALITY material, you OBTAIN durable products with our experts.

Grab ONLY durable products as per YOUR EXPECTATION.

Overall Appearance

Is PRODUCT according to the client’s SPECIFICATIONS? We check by looking at the EXTERNAL appearance of the products. Our agents check the DIMENSIONS and sizes of the product. From Every ASPECT, we SECURE AQL standards.

So get the REQUIRED product with exact specifications.

Product Size and Weight

Our agents thoroughly check the PRODUCT size and WEIGHT. Heavyweight inventory with LARGE size charges you EXTRA bucks while shipping. So we REDUCE it in the BEST way by following an AQL rule.

Procure products with EXACT WEIGHT and SIZE.

Advantages of AQL Inspection

Thorough examination with REPORTS

Our inspectors check out everything ABOUT your product. We focus on SAFETY hazards. Remove the TOXIC products.

The final OUTPUT is 100% QUALITATIVE products.

Get your inspection report to BUILD confidence.

STANDARD product QUANTITY with fewer defects

We check:

- Product QUANTITY with MINOR DEFECTS

- PRODUCT QUANTITY with MAJOR defects

- Does the product fall into your AQL levels?

If everything is FINE, we send you the ITEMS.

You get less defective inventory that qualifies your ACCEPTABLE quality limit.

Profitable business

We prepare the AQL Inspections.

You get QUALITY products with us. Sell THEM and MAKE your business MORE PROFITABLE.

More money INFLOW would let your BUSINESS boom!

Our approach

Why Perform Your AQL Inspection at Leeline Sourcing?

- Reliable SERVICES. We have a TRAINED staff to do an in-depth inspection at different INSPECTION levels. Years Of EXPERTISE puts on the TOP. You will be our LONG-TERM customer once you try our services.

- Dedicated AGENTS. Once you CONTACT us, we specify an EXPERT agent for inspection. Our agent provides you with ALL the AQL SOLUTIONS instantly.

- Ensure QUALITY. We ensure QUALITY services. Our inspectors get the sample size. Prepare an INSPECTION REPORT. And REMOVE items with CRITICAL defects. You obtain 100% QUALITATIVE products.

- Solution for END-to-END AQL inspection. We are READY to assist you at every step regarding your AQL inspection. The FINAL production always QUALIFIES your AQL standards.

Any Problem You Need about Quality Inspection, We Can Help!

Don’t hesitate to contact us!

our satisfied Clients

2000+ Clients Trust LeelineSourcing

I sourced all kinds of stuff for my company for about 1 year with Leelin. They have really good service, their team is polite and trustworthy. I definitely recommend you to work with them.

Levi

I worked with Leelin for 2-3 years to build my brand. They check each item and does my customs clearance get into Amazon warehouse. I love their service, it saves me a lot of time. If you are also developing your business in China, they will help you do it smoothly.

Belinda

Working with Leelin is really positive, they are honest and reliable. I recommend their services to anyone who has a business that needs to ship products from china or needs to inspect items.

Julie

AQL Inspection: A Mega Guide

Searching out the SECRET to SUCCESS?

It is QUALITY. Clients Want long-term solutions. And YOU provide them with that SOLUTION.

At this PHASE, AQL Inspection is CRUCIAL.

Our QUALITY control professionals have ROCKED in the QUALITY control industry. Flawless APPROACH and CONTINUOUS PRACTICE reached the HEIGHTS of business. Boost your sales with us.

Always FOCUS on an AQL standard PATTERN. No compromise on QUALITY at all.

Want to know more ABOUT AQL? This GUIDE HIGHLIGHTS what you want about the Acceptable QUALITY limit.

Ride the TIDE. Let’s MAKE more of it.

- Get an AQL Quality Check With Leeline Sourcing

- Advantages of AQL Inspection

- Why Perform Your AQL Inspection at Leeline Sourcing?

- Any Problem You Need about Quality Inspection, We Can Help!

- our satisfied Clients

- 2000+ Clients Trust LeelineSourcing

- AQL Inspection: A Mega Guide

- What Is AQL Inspection?

- What Are The Three Levels Of AQL General Inspection?

- Why Do You Need AQL Inspection?

- How Do You Select AQL Inspection Levels?

- How to Use the AQL Tables: Step-by-step Guide

- Crucial things to understand about the AQL Chart

- FAQs about AQL Inspection

- What’s Next

- Do you want a successful import business?

What Is AQL Inspection?

AQL refers to the ACCEPTABLE QUALITY LIMIT. In QUALITY control, AQL refers to the number of DEFECTIVE PRODUCTS.

Usually, we calculate it in percentages. If a client asks for 2.5 AQL, it simply MEANS:

The final number of items must not contain DEFECTS more than 2.5 percent.

You REGARD it the THRESHOLD of the defective UNITS.

Inspection, Supplier Audit, Product Testing in China & Asia

We focus exclusively on QUALITY CONTROL. Today hundreds of clients worldwide have selected to trust Leeline Service as their partner for supply chain Management.

What Are The Three Levels Of AQL General Inspection?

General INSPECTION comprises THREE different levels. Each level defines the PRODUCT quality and CHECKS the integrity.

Let’s check them out!

General Inspection Level I:

Acceptable Quality LEVEL I refers to the product inspections for LOW AMOUNT INVENTORY.

- It defines the QUALITY of the product.

- Sorts out the CRITICAL defects per Acceptable quality limit.

- It is a GOOD choice when you already have worked with the SUPPLIER. The third-party inspectors will help you DETECT the major defects.

General Inspection Level II:

General Inspection Level II is a DEFAULT level. If you APPOINT the inspector, it will be ACCEPTABLE QUALITY LIMIT II.

- It is good if you have GONE for the FIRST interaction with your SUPPLIER.

- A fair amount of products is ENOUGH to check on this AQL level.

- A thorough examination FILTERS out the products with MAJOR DEFECTS.

General Inspection Level III:

How many UNITS do you have to INSPECT?

Is the number of PRODUCTS high?

If so, we have a ROCKSTAR! PRETTY affordable for HIGH quality with AQL limits.

Inspection level III is PREFERABLE for a HIGH quantity of items. Level III needs large teams and deeper understanding. It may be time taking but if you have a skilled inspector, then it’s easy. Leelinesourcing has some of the most experienced inspectors in the industry.

Here is what you SHOULD know about this.

- It is a TIME-CONSUMING process. Because the inspectors check the AQL value in a large number of items.

- You can CHOOSE it whether the SUPPLIER is new or OLD.

Your INSPECTORS provide inspection results ASAP!

Why Do You Need AQL Inspection?

AQL inspection comes up with MANY reasons to fall for this METHOD.

Curious to KNOW? CHECK OUT why it is a GAME CHANGER.

- Sample SIZE is easier to FIND

Sample SIZE is a BIGGER problem than you might think.

If you have 1200 products, how do you even DETERMINE the sample size?

AQL inspection makes it MORE EASIER.

AQL charts describe the SAMPLE category. You don’t WASTE hours choosing the SAMPLES.

SIMPLE AND ACCURATE METHOD FOR SAMPLE SIZE.

They Check samples on the quality standards set by you. You get a report on its defects and flaws if it does not comply with it.

- You get STANDARD QUALITY products

Since you SET standard VALUE, you get it.

For EXAMPLE, if you want AQL to be 1, simple.

Get 100 samples. Test them. Only 1 MUST have the MAJOR defect. More than ONE is NOT ACCEPTABLE.

So you get HIGH STANDARD inventory.

- Cost-effective Option

It is an INEXPENSIVE option. You HIRE the INSPECTORS at the BEST POSSIBLE prices.

Save time and money with the systematic approach of AQL inspection.

You SAVE money!

How Do You Select AQL Inspection Levels?

There are TWO levels of INSPECTION.

It is a SPECIFIC situation in which you should use them.

- The type of PRODUCTS

Applying AQL to susceptible products?

Set AQL as:

- Critical defects to be zero percent.

- The major defect ratio must be one or less.

- The minor defect ratio should be 2-3 percent.

Usually, the GENERAL INSPECTION level is GOOD. For high-end items, you can PREFER specific inspections. Share your specific targeted areas for High-End products. If it’s an electronic product, then be more precise about quality checks.

- The batch size

How many consumer products do you want?

Batch size is QUITE crucial to help find the RELEVANT INSPECTION METHOD.

For a smaller sample, choose GI. For large SAMPLE, consider AQL level GIII.

- Market trends

Depending on the market TRENDS, you can set the LOW value of your AQL.

Focus on CUSTOMERS’ preference. Go and ROCK, then.

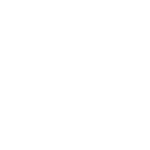

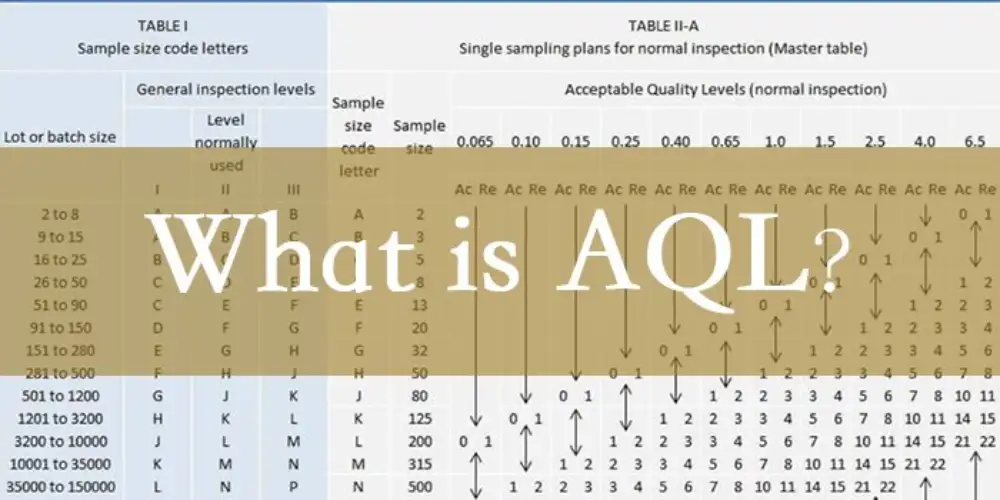

How to Use the AQL Tables: Step-by-step Guide

ANSI ASQ Z1.4 AQL standard table acts as an AQL calculator.

Here are FOUR STEPS to be the KING of it.

Step 1: Choose INSPECTION TYPE and LEVEL

Choose your INSPECTION type. Here are TWO KINGMAKER inspection types.

- General Inspection level

- Special inspection level

We already have a HIGHLIGHTED general INSPECTION level. Usually, sellers PREFER this option because it CHECKS generally. LEVEL II is the default option, but you can choose any specific option. You must be clear about your requirements and quantity level. Further sellers guide you a lot.

When SPECIFIC products are checked, the inspection finds significant and MINOR defects.

Step 2: Find sample size Code letters

Sample SIZE code letters are QUITE CRUCIAL. THEY EVEN define the WHOLE table.

So, it is ESSENTIAL to look at a SAMPLE size code letter and GO for your SPECIFIC type.

AQL CHART has DIFFERENT columns. Check out the RELEVANT column in the AQL chart.

For example, if you have 5 PRODUCTS. And you prefer the GENERAL INSPECTION level II. Check out the K under the INSPECTION column. Find the AQL sample size according to the given sample size code letter. Let’s suppose it is 1201-3200 in your TABLE.

Step 3: Choose Acceptance Quality Limit for your product

Once you have UNDERSTOOD the graph, it is NO LONGER a problem.

Get your AQL sample size. Ask the INSPECTOR to check the number of PRODUCTS per the AQL sample size.

Sampling inspections highlights:

- Critical defects

- Minor defects

- Major defects

A HIGH AQL means you allow a HIGHER percentage of defective products. A low AQL describes a low number of products with major or MINOR defects.

Check your ACCEPTABLE quality limit as per your CHOICE.

Step 4: Know ACCEPT and REJECT points

AQL sample size and INSPECTION give you the CHOICE to reject or accept the products.

If products don’t QUALIFY AQL, you ask the supplier to reduce major or MINOR defects. It helps you to maintain the quality of your product. Share your concerns with the supplier deeply so he can fix them.

Crucial things to understand about the AQL Chart

Don’t know how to read the TWO TABLES on the AQL chart?

Whether you are TESTING the first or SECOND table, here are some points you must know.

Sampling Size

Sampling SIZE is derivative of the GRAPH.

For example, if you have 1000 watches. You can’t inspect the ENTIRE batch. Choose a MINIMUM number of products to CHECK.

Define how many cartons you want to INSPECT.

AQL charts help get AQL sample size.

Inspection Types

There are TWO FUNDAMENTAL inspection types.

Each inspection TYPE has different LEVELS. Understand which LEVEL you want and need to maintain quality. Choose accordion to your inventory size and quality standard requirements.

Here are the inspection types.

- General inspection. It has THREE levels. GI, GII, and GIII.

- Special Inspection. It has FOUR levels. S1, S2, S3, and S4.

Lot Size

LOT size defines the TOTAL number of products to be CHECKED for CRITICAL defects.

The batch size COLUMN indicates the category you MUST follow.

During the SAMPLING inspection, you must know the LOT SIZE. And get your SAMPLE size as per INSPECTION levels.

Acceptable QUALITY limit

Acceptable QUALITY limits define:

- The product with critical defects.

- Number of units with minor defects

- The number of units with MAJOR DEFECTS.

As per the CERTAIN function, you MUST know:

- Acceptance number

- AQL inspections

- AQL standards.

For AQL 2, the products are CONSIDERED acceptable whether they have defects in 2% or fewer units. Yet if the Defect is more than 2%, you could ask for a replacement. In most cases, they repair or change the defective items. Inspect them again before accepting the inventory.

Looking for the Best China Sourcing Agent?

Leeline Sourcing helps you find factories, get competitive prices, follow up production, ensure quality and deliver products to the door.

FAQs about AQL Inspection

1. Why use AQL instead of inspecting 100% of your products?

AQL is a GOOD choice because:

· It charges less

· Consume less time than 100% inspection.

· Worst tolerable and BEST tolerable is easy to FIND.

· You get an IDEA of consumer products with a MAJOR or MINOR defect.

2. Is lower AQL better?

Yes. THAT IS 100% TRUE. There are MANY reasons.

· You sort out the QUALITY level.

· It is INEXPENSIVE.

· The sample plan is FAR EASIER.

A set AQL level guides better

3. What are the risks of reducing the sample size?

Reducing the SAMPLE size comes up with many problems. For example:

· You might not GET the required OUTPUT results.

· Less sampling might HIDE safety hazards.

· Potential defects can’t be DETECTED with a smaller sample size.

4. Does AQL guarantee my products have zero defects?

Yes. If you have product level requirements of CRITICAL defect 0, major 1, and MINOR defect 3. That means you will receive the products with the REQUIRED defects.

So, you get INVENTORY as per requirements.

What’s Next

Never COMPROMISE on QUALITY.

Is that statement True?

Yes, 100% TRUE. But for inspection, you must know QUALITY levels. Product Failure occurs when you don’t HIRE the RIGHT company.

Get in TOUCH with LEELINE SOURCING. Our experts procure a DECADE of experience in sorting out QUALITY products. We’ll help you GET the right solution.

Hit us a CALL right away!

Related Resources

Ecommerce Business Guide

Do you want a successful import business?

Hey, I’m Sharline, co-founder of LeelineSourcing. We’ve helped 2000+ customers import from China.

Do you want a better price on product or shipping?