Destination: Thailand

Client: OnePlus Thailand

Lead Time: 45 Days

Challenges:

Phone Case: Distortion of the case structure, issues with thermal transfer printing, and alignment of water decals.

Ring Holder: Complications with oil spraying, thermal transfer printing, and placement of water decals.

Packaging Box: Modifications to the design draft, printing challenges, surface finishing, and packaging logistics.

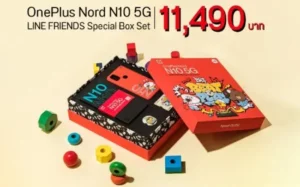

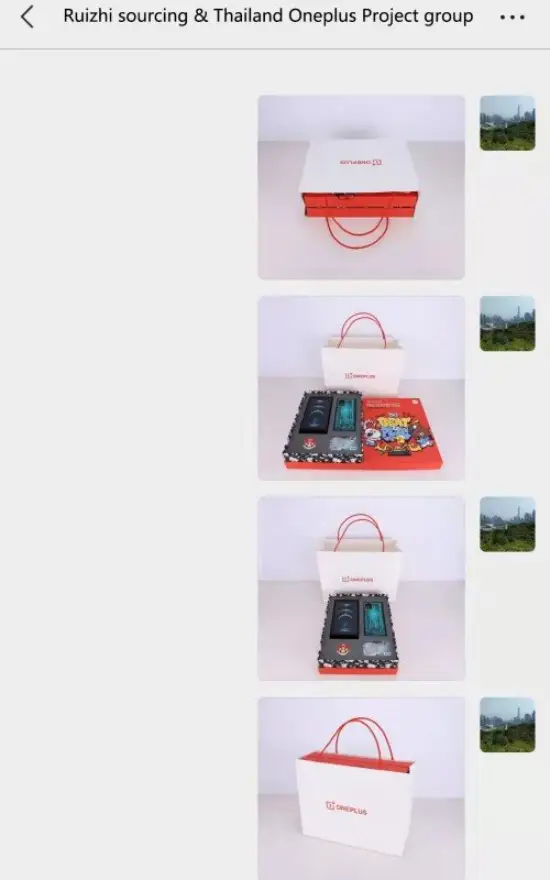

OnePlus Nord N10 & LINE FRIENDS Exclusive Box Set

Background on OnePlus Thailand Collaboration

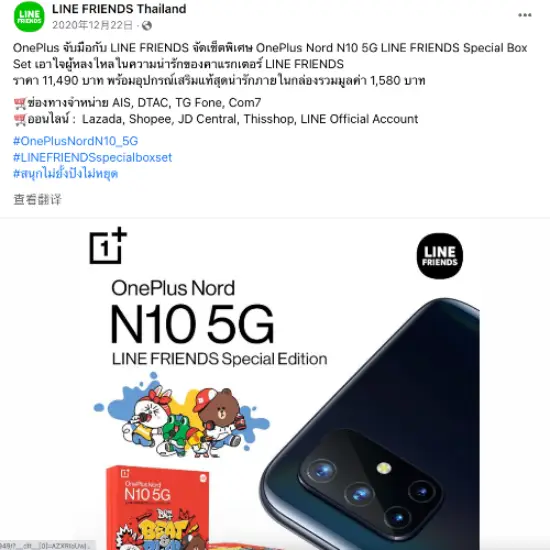

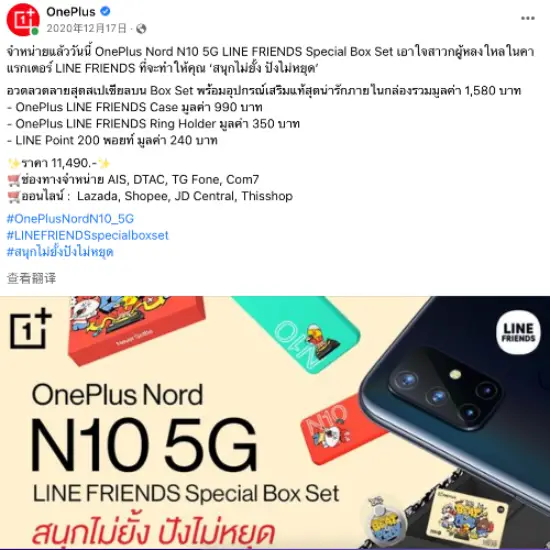

OnePlus Thailand, in partnership with the popular instant messaging service Line, is gearing up for a promotional campaign to mark the launch of their new smartphone, the N10. This campaign will feature a co-branded package, offering a special four-piece gift set with every purchase of the OnePlus N10. The gift set is designed to enhance the strategic alliance between OnePlus and Line, containing an N10 smartphone, a custom phone case, a ring holder, and an exclusive VIP shopping card.

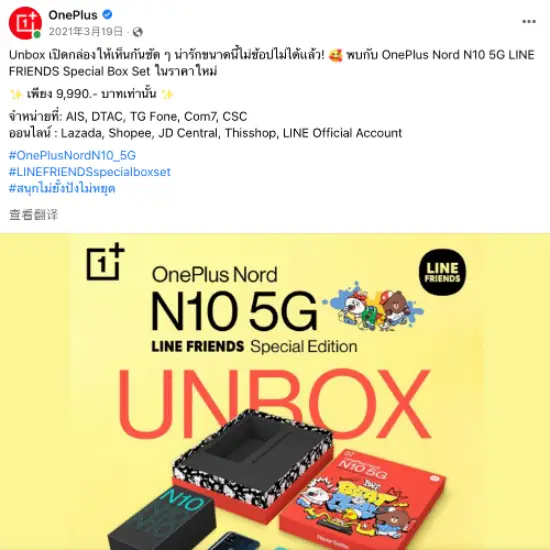

Coverage by Thai Media on OnePlus N10 Launch and Promotional Gifts

Initial Requirements from OnePlus Thailand

Outlined below is a summary of the initial specifications provided by OnePlus Thailand for the promotional items:

Client Chat Record

- Handmade Luxury Gift Box: Utilizing 250gsm double-coated paper with a tactile film finish, reinforced with 1500gsm greyboard, featuring internal printing in 18 spot colors plus 4 process colors.

- Smartphone Case for N10: Comprised of 2mm thick TPU material, finished with a rubber oil spray and adorned with thermal transfer printing in 6-8 spot colors.

- Ring Holder: Crafted from acrylic, finished with an oil spray and thermal transfer printing in 3-5 spot colors.

- Tote Bag: Made from 300gsm single-coated board, printed in spot colors with a red nylon carry cord.

Project Specifications:

- Quality Expectation: High

- Budget Sensitivity: Medium

- Timeframe Urgency: High

- Complexity Level: High

Engagement with Manufacturing Partners

Between November 12 and November 16, 2020, our team engaged in detailed discussions with three long-standing manufacturing partners to clarify product specifications, process requirements, and potential challenges. The discussions involved:

- Phone Case Manufacturer — ****

- Ring Buckle Manufacturer — ****

- Packaging Box Manufacturer — ****

Internal Review by LeelineSourcing Team

Following extensive consultations with both the factories and the client, our team convened to address and strategize solutions for identified production challenges:

Challenges in Phone Case Production:

- Deformation Concerns: The 2mm TPU phone cases, treated with a hanging spray method of rubber oil application, were prone to deformation at high furnace temperatures of 65-70°C.

- Solution: Post-heating, the cases will be placed on a flat surface and re-enter the furnace for reshaping to maintain form.

- Thermal Transfer Printing Issues: The application of 6-8 spot colors in thermal transfer printing was susceptible to color misalignment, leading to white gaps.

- Solution: Adjustments in the design’s color separation and the addition of an underlay sticker during thermal transfer will ensure color integrity and prevent white gaps, maintaining the clarity and vibrancy of the print.

- Water Decal Alignment: The placement of water decals during thermal transfer printing was inconsistent.

- Solution: The creation of a specialized positioning tool for the phone case decals will standardize the application process, ensuring uniform placement.

Challenges in Ring Buckle Production:

- Oil Accumulation in Rotating Joints: The oil spray process on the ring buckles led to excess oil accumulation at the pivot points, causing the oil layer to peel off upon rotation.

- Solution: Switching from automatic to manual oil application, specifically avoiding the rotation areas to prevent buildup and peeling.

- Thermal Transfer Printing Complications: Similar to the phone cases, the ring buckles faced challenges with color fidelity in thermal transfer printing, leading to white gaps.

- Solution: Implementing a refined color separation technique and using a sticker underlay during thermal transfer to ensure a seamless and accurate color application, avoiding any white gaps.

- Consistency in Water Decal Placement: The positioning of water decals on the ring buckles during thermal transfer printing was prone to misalignment.

- Solution: Developing a custom positioning tool for the ring buckle decals to achieve consistent and accurate placement.

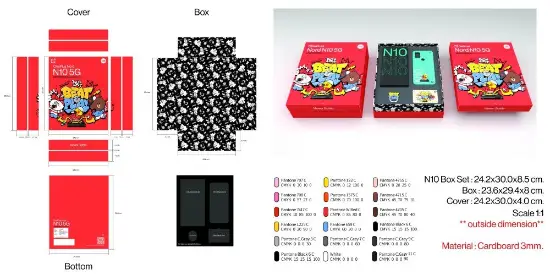

Challenges in Crafting the Color Box:

- Design Draft Adjustments: The client’s ideal design featured 18 spot colors combined with 4-color printing. However, the complexity of accurately reproducing 18 distinct colors posed risks of color bleeding and white gaps, especially where different color blocks meet.

- Solution: To maintain the integrity of the design while preventing color issues, each spot color block was re-separated and expanded to ensure clear presentation and avoid white leakage. The imprint printing method was chosen for its precision in maintaining the vibrancy and clarity of each color.

- Printing Process: The printing was planned with a 5-color press, utilizing 5 channels for spot colors. Each color was to be matched with the Pantone system for accuracy. The challenge arose from potential color block shifts and distortion if there were significant pauses between processes, such as overnight breaks.

- Solution: To prevent any misalignment or distortion of color blocks due to process delays, additional personnel were allocated from other departments to bolster the workforce, ensuring a seamless and continuous printing operation.

- Surface Treatment: The chosen tactile film for the box surface had poor glue absorption, necessitating manual application and precise alignment at every corner. Inexperienced handling could result in visible fingerprints, detracting from the box’s premium feel.

- Solution: Only skilled workers with experience in delicate surface treatments were tasked with this phase, minimizing the risk of imperfections and ensuring a flawless finish.

- Packaging Transportation: The luxury handmade boxes faced a risk of damage under weight or during transit, with potential for the packaging to be crushed or squeezed.

- Solution: To safeguard the boxes during transportation, each was individually wrapped in a bubble bag, with a packing strategy of 10 boxes per outer carton, ensuring protection against transit-related damage.

Final Sample Approval and Delivery

Over a span of ten days, we conducted two rounds of prototyping, making precise adjustments to the color and design details. The efforts resulted in the mobile phone case, ring buckle, VIP card, and packaging box achieving a 95-98% match with the original design specifications. Following a video confirmation with the client, the finalized samples were sent to OnePlus in Thailand for final approval.

Phone Case for N10

Ring Buckle for N10

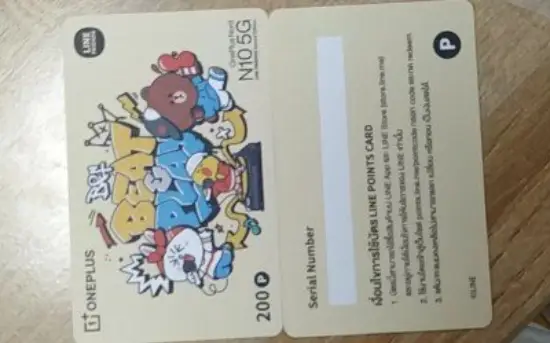

VIP Card for N10

Receipt of Purchase Order

Upon reviewing the samples, OnePlus Thailand expressed their approval and satisfaction, subsequently placing an order with LeelineSourcing. The order specified a delivery timeline of 20 days to the designated logistics partner.

Quality Assurance and Logistics Coordination

We conducted on-site quality checks at each of the three supplier facilities, approving the production batches after successful spot checks. Following approval, we instructed the factories to proceed with shipping, while simultaneously preparing the necessary export documentation and completing customs declarations for the outbound goods.

About the Author

Sharline : Your China Sourcing & Shipping Expert

Hey I’m Sharline, the founder of LeelineSourcing. As an expert in sourcing products from China , we helps buyers find high quality product and best suppliers to optimize your supply chain . We has extensive experience vetting suppliers, negotiating deals, inspecting products, combining orders, and organizing shipping.

We understands Chinese market and business culture well, which helps you always get the best deal for clients. With 15 years of experience in the field of sourcing in China, we have helped 5000+ clients import from Alibaba, 1688, Taobao to Amazon FBA , Etsy, Ebay and Shopify.

Work with LeelineSourcing to solve your product sourcing needs, you can expect:

- Streamlined ordering process: You focus on running your business, as LeelineSourcing will handle everything from sourcing to shipping.

- Expert negotiation: You get the best possible supplier and deal, saving you a lot of headaches.

- Quality assurance: Your order will be inspected before the delivery, so you get what you paid for.

- Efficient logistics: Your orders from multiple suppliers can be consolidated and shipped to your doorstep. Save shipping costs and increase business profits.

Partner with Sharline and skyrocket your business profit.

Struggling with China sourcing and shipping?

LeelineSourcing can help! We offer a unique solution to source premium supplier, fulfill your orders easier, boost your profits, and simplify your business.. We’ve helped 5000+ customers import from China.